The day before, London is using 3D printing technology to build the underground tunnels, the expansion of the train network. The 3D print casting system means that it is now more expensive than ever before to produce complex molds with innovative shapes and gorgeous details. The project is expected to add 42 billion pounds to the UK economy.

Crossrail in London, England, is a 14 billion 800 million pound (over one hundred billion yuan) expansion of the London underground rail network project, is now using 3D printing technology to build a tunnel. Crossrail is the world's first large-scale commercial construction project using 3D printing.

A total length of 100 km, across the East and West, 40 stations, the project is Europe's largest construction projects. The new tunnel under construction will be named Elizabeth line.

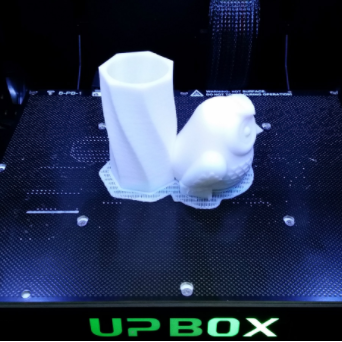

The FreeFab method adopted in the project itself, through 3D printing high precision wax instead of concrete. FreeFAB has several key advantages. One is the structural integrity and strength, builders can realize complex shapes both light and incredible, while bypassing the traditional problems with 3D printing of concrete in large buildings in Australia; secondly, the invention cause mould technology less waste; on the other hand, FreeFAB wax can be melted into the tank, and re extrusion as a new form of 3D; finally, this print casting system means that now more than ever cheaper to produce complex mold with innovative shapes and ornate details.

All these advantages are now playing a part in the construction of a large new underground train line in london. Currently, hundreds of concrete slabs are being installed at Crossrail's passenger tunnel, which covers more than 100 kilometers.

The Elizabeth line is expected to be fully operational by the end of 2019, with an estimated capacity of 200 million passengers per year and an increase of 10% in the capacity of the railway network. Although the initial investment is huge, the project is expected to bring in 42 billion pounds of revenue for the UK economy.

Keyword in this article: